Case Study – Zep’s Pre-Treatment EQ Tank Upgrade with MOB

Zep's Pre-Treatment EQ Tank Upgrade with MOB

Zep’s Challenges

Chambersburg, PA

Zep is a leading innovator of cleaning solutions for retail, food & beverage, industrial & institutional, and vehicle care customers. For over 80 years, Zep has developed the most effective products trusted by professionals and consumers across the globe. Zep’s chemical manufacturing process generates 35,000 gpd of wastewater high in COD, quaternary ammonium, peracetic acid and other biological inhibitors, which requires substantial pre-treatment for safe discharge into the local municipal WWTP with a 400 mg COD/L limit. It was a tough challenge. Zep’s pre-treatment facility had just one aeration EQ tank for all the wastewater before discharge. It could handle around 10% COD removal, but that was not nearly enough to achieve the 400 mg/L goal when influent COD was constantly hovering above 3000 mg/L. With spikes of inhibitors and toxicity, short HRT (4 hrs), and limited space and configuration, most biological treatment approaches would be unsuitable for this task, making the discharge limit unattainable.

MOB Process Integration

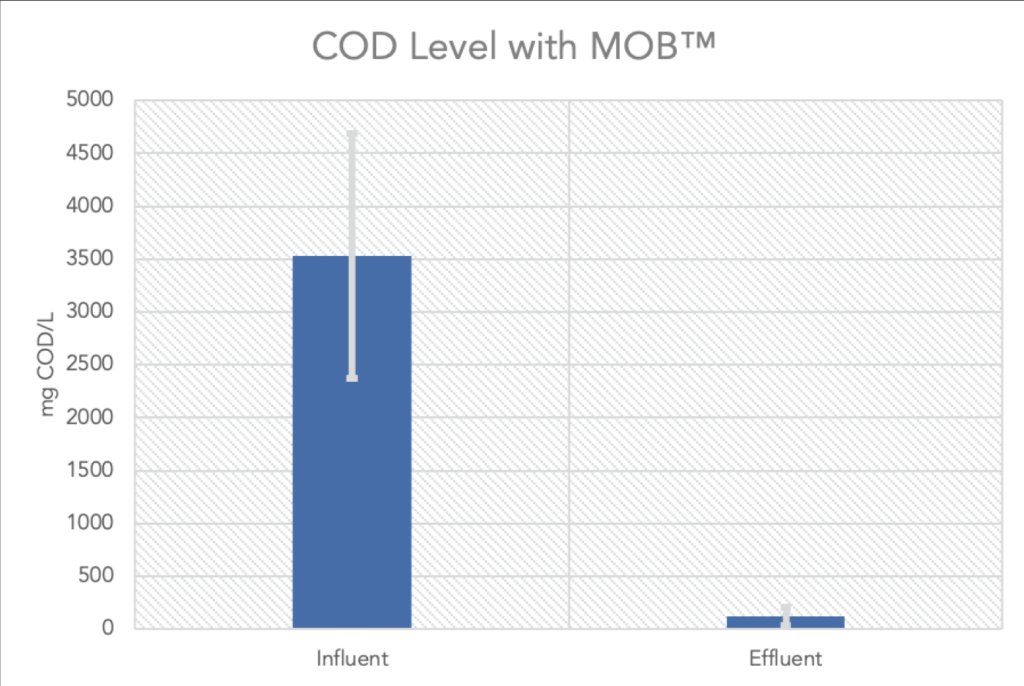

The bioaugmentation introduced by MOB into Zep’s aerated EQ tank not only immediately increased the treatment capacity, but also eliminated frequent upsets. Thanks to the Nuvoda ballasted media’s naturally high surface area and carefully engineered shape and size, MOB Process was able to resist harsh conditions by developing a dense and concentrated biofilm community in the EQ tank. The robust and time & cost-effective MOB Process achieved 95-99% COD removal efficiency, bringing the effluent quality well within compliance.

“We have consistently seen >95% COD reduction, which brings 3000~5000 ppm of COD down to below 100 ppm. No other biological processes than MOB could have achieved this performance whilst being resistant to all the chemicals in our waste stream. The stability of MOB process is truly one of a kind.”

Todd Cornwell, Director of Water Group | AFCO/Zep

Let us help you achieve your treatment goals!

Call: (919) 615-1205 | Email: sales@nuvodaus.com