Case Study – West Virginia POTW

West Virginia Wastewater Treatment Plant Upgrade Utilizing the MOB Process

Challenges

In 2013, a partnership between the Town of Moorefield, West Virginia and local poultry factory1 resulted in the construction of the 6.2 MGD Advanced Nutrient Wastewater Treatment Plant (WWTP) to improve the region’s discharge quality into the Chesapeake Bay Watershed (See above photo). The state-of-the-art 5-stage biological treatment process currently treats a combination of industrial (90%) and municipal (10%) flow to meet the stringent discharge limits. Soon after start-up, the Moorefield WWTP encountered multiple issues caused by the waste flow from the poultry process. The variable industrial influent is high in nutrient concentration but low in BOD; this forced the WWTP to rely heavily on expensive chemicals to meet the discharge limits. Moreover, the sanitation chemicals from the industrial process caused several biological upsets in 2016, costing the Moorefield WWTP $200,000 to recover.

Nuvoda’s Solution – The MOB Process

Faced with high operation cost and unpredictable effluent quality, the Town of Moorefield WWTP underwent a process upgrade using Nuvoda’s MOB Process in March 2017.

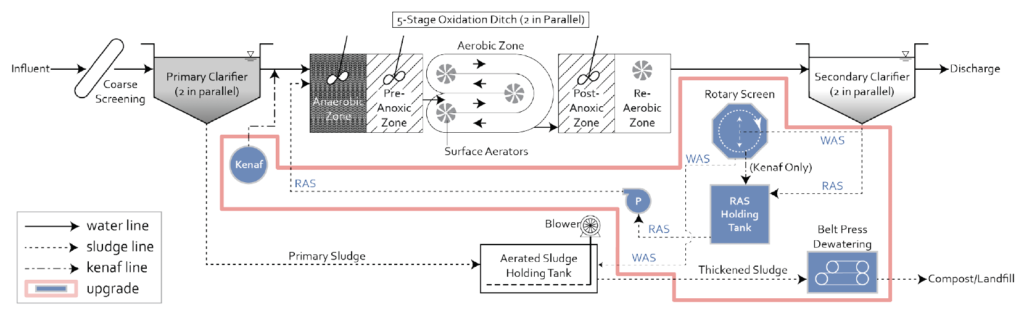

Figure 2. Moorefield wastewater treatment process overview and Nuvoda’s upgrades. The original treatment process includes a rake bar screen to prevent large debris from going into the treatment train, two parallel primary clarifiers, two parallel 5-stage bioreactors, 2 parallel secondary clarifiers, aerated sludge holding tanks and a sludge dewatering station. Nuvoda’s upgrades include Kenaf addition into the 5-stage bioreactor, a 300 GPM rotary screen for media catchment and recycling, RAS lines and pumps to return the media in the bioreactor, and a belt press dewatering system.

The MOB (Mobile Organic Biofilm) process is a novel and sustainable wastewater treatment process developed by Nuvoda to improve settleability, increase treatment capacity, provide simultaneous nutrient removal, and optimize process stability (Figure 3 – 6).

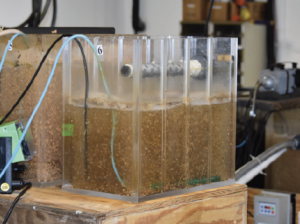

Figure 4. Kenaf in a pilot reactor

Figure 6. Biofilm growing on a Kenaf particle.

Figure 5. Kenaf particles have a highly textured surface to support biofilm growth.

Figure 4. Kenaf in a pilot reactor

The patented MOB process utilizes a highly renewable, naturally occur-ring lignocellulosic material harvest-ed from the fast-growing Kenaf plant (Hibiscus cannabinus) as a substratum for biofilm growth. The adsorptive and high surface area Kenaf is machined to approximately 500 µm in size, allowing the particles to act as optimal media for hybridized fixed film and granular sludge growth. This hybrid matrix of fixed film and granulation is fully “mobile” and free to circulate throughout the process, and adaptively grows a stratified microbial community that facilitates robust and versatile simultaneous biological nutrient removal. Free to circulate into the secondary clarifier, the hybrid matrix improves settleability, reduces effluent TSS, increases clarifier capacity and makes dewatering sludge more efficient.

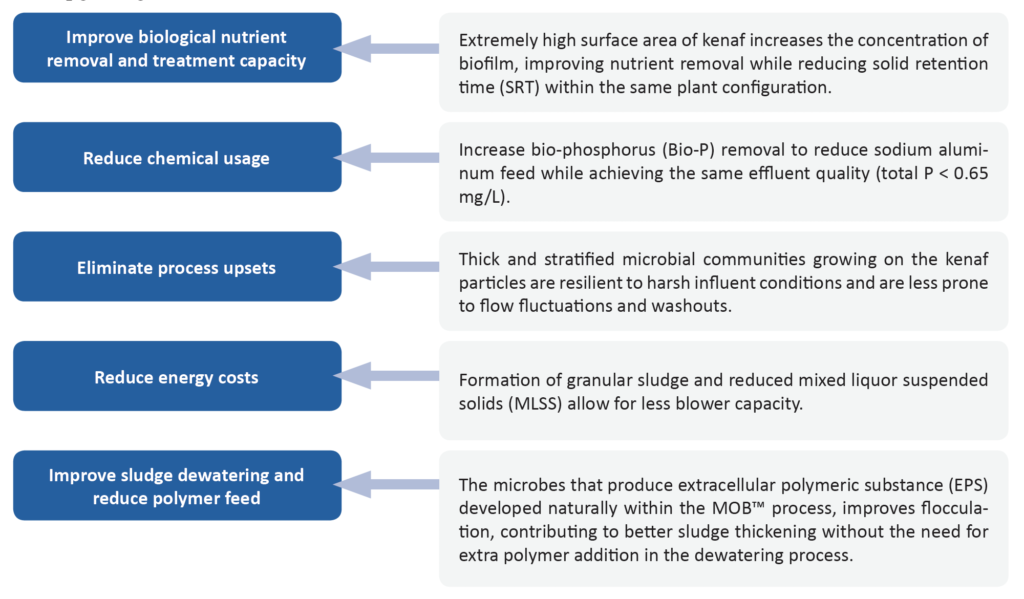

The Moorefield WWTP upgrade included 9.5×107 m2 of Kenaf added to the 6.2 MGD 5-stage bioreactor, a 300 GPM drum screen for media recycling, RAS lines, and a belt press sludge dewatering system (Figure 2). The upgrade goals for Moorefield WWTP are listed below:

MOB Process Upgrade Results

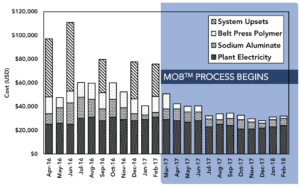

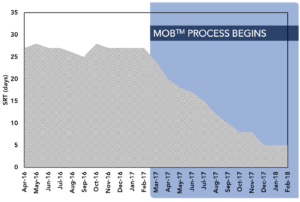

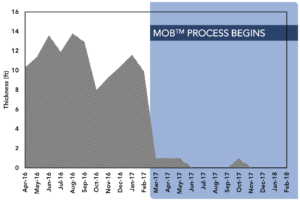

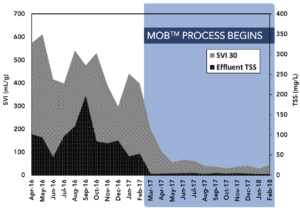

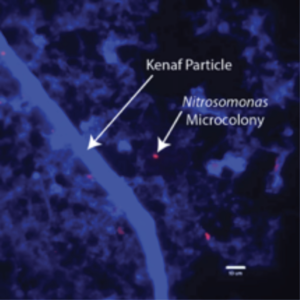

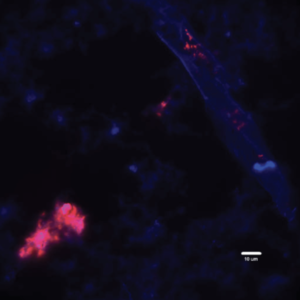

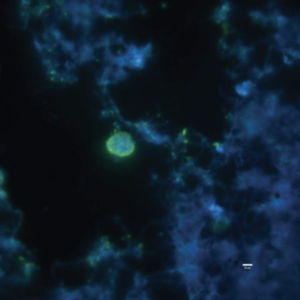

Figures 7 – 10 represent data collected from the Moorefield WWTP over a period of two years, April 2016 to February 2018, a year before and after the installation of the MOB Process in March 2017. Overall, the MOB Process has achieved all treatment goals, provided a layer of protection against biological upsets, and has increased the rate of recovery from high and unpredictable industrial loadings. Furthermore, the MOB Process has drastically improved settleability, and in turn, completely eliminated previous washout and reseeding events. The sludge blanket, SVI, and TSS all dropped by 86% to 97%, while producing high effluent quality. Figures 11 – 15 demonstrate the diverse microbial communities harvested from the Moorefield WWTP, using fluorescent in situ hybridization (FISH) technique and fluorescent microscopy.

Figure 7. Monthly cost breakdown of the Moorefield WWTP since April 2016. The MOB™ Process has decreased the total monthly usage as well as individual usage in electricity, sodium aluminate, and belt press polymer. More importantly, the MOB™ process has eliminated system upsets since the March 2017 installation. |

Figure 8. Monthly average solid retention time (SRT) since April 2016. The MOB™ process has been able to consistently decrease the SRT from 25 days to 5 days since the installation in March 2017. Kenaf’s high surface area can support concentrated biofilm growth, increasing the treatment capacity by at least 75% within the same reactor configuration. |

Figure 9. Sludge blanket thickness in the secondary clarifiers improved from an average of 11 ft to 1 ft as a result of the high settleability of the hybrid matrix. |

Figure 10. 30-min Sludge Volume Index (SVI30) and Effluent TSS decreased significantly from an average of 460 mL/g and 90 mg/L to an average of 60 mL/g and 4 mg/L, respectively since March 2017. |

The 5-stage biological treatment con-sisting of anaerobic, anoxic, aerobic, post-anoxic and re-aerobic stages facilitates the growth of nitrifiers, PAOs and anammox, leading to simultaneous nutrient removal in the process. The following FISH micrographs using a variety of probes showcase diverse microbial colonies developed in the MOB Process.

Figure 11. Anammox bacterial colonies shown in red.

Figure 12. Ammonia-oxidizing Nitrosomonas microcolonies shown in red. |

Figure 13. Ammonia-oxidizing Nitrosomonas microcolonies shown in red. |

Figure 14. Nitrosospira shown in red. |

Figure 15. Phosphorus accumulating organisms (PAOs) shown in green. |

Let us help you achieve your treatment goals!

Call: (919) 615-1205 | Email: sales@nuvodaus.com

1 Pilgrim’s Pride, localities unite to build wastewater Plant

https://www.bayjournal.com/article/pilgrims_pride_localities_unite_to_build_wastewater_plant